Load Weight and Wheel Size

The first consideration for caster selection is to determine the combined weight of the equipment and maximum load on this equipment. Generally, the greater the weight, the larger the wheel required for the caster. Larger wheels distribute weight and roll more easily over floor obstructions.

To determine the load capacity for each caster, divide the combined weight of the equipment and maximum load by the number of casters to be used. This is the load that each caster and wheel must support. Always select a caster and wheel that are rated for a capacity greater than the calculated load per caster. This allows for unusual conditions that could change the performance of the caster.

Wheel Choice

As a general rule, hard tread wheels perform better on soft or smooth floors and soft tread wheels roll better on hard or rough floors including outdoor surfaces. When choosing a wheel type, take into consideration all special floor conditions- tracks, gutters, grates, sills, elevator thresholds, seams and dock plates. The larger and softer the wheel, the greater the ability to roll over rails and similar obstacles. To protect floors from damage, choose softer cushion tread wheels. Solid Cushion Rubber,TPR(thermoplastic rubber), High Modulus Rubber and Pneumatic Rubber wheels will provide quiet operation and maximum floor protection. Steel and Cast Iron wheels are not recommended for floor protection, but they are well suited for industrial applications.

Polyurethane wheels like cast iron polyurethane wheels are frequently and effective compromise giving moderate floor protection with greater load capacity.

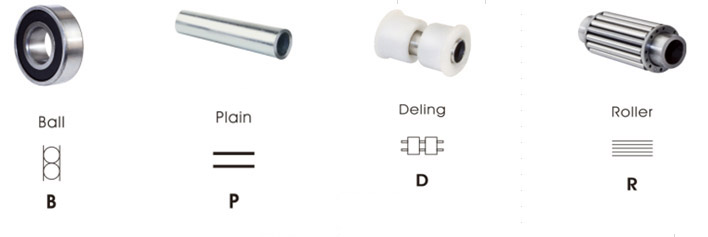

Wheel Bearing

- Plain Bearing:

Wheel bearing bore riding directly on the spanner bushing and/or axle. - Ball Bearing:

Recommended for loads where maximum rolling ease is required. They require less effort to start rolling and keep rolling than other bearing types. - Roller Bearing:

This bearing carries greater loads than same size ball bearing. Well suited for heavier, industrial uses. - Deling Bearing:

An economical bearing well suited to conditions of frequent exposure to water, steam cleaning, salts, brine and corrosive conditions. - Flange bearing:

Non-precision industrial grade bearings are press-fitted into wheel hubs.

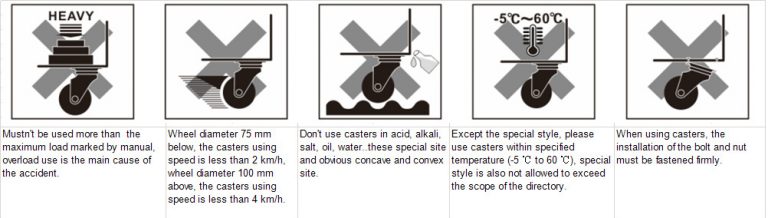

Caster Maintenance and Inspection

Check the swivel assembly for excessive play due to wear. If the swivel assembly is loose, it is advisable to replace the fork of the entire caster. If the caster has a king bolts and nut, make sure it is fastened securely. If the swivel does not turn freely, check for corrosion or dirt binding the raceways. Again, it may be necessary to replace the swivel assembly or the entire caster. If the equipment has rigid casters at ton end ,make sure that the caster fork legs are not bent or distorted.

Wheel Maintenance and Inspection

Check wheels for visible tread wear. Flat spots may indicate accumulation of floor debris such as string or thread which can cause the wheel to bind. Remove the wheel axle bolt and nut. Clean out foreign material and check wheel bearings for wear or failure. Re-assemble if parts are not damaged. Wheel thread guards may be installed to reduce buildup if string and thread wrapping is a continuing problem. After wheels have been inspected and repaired or replaced, be sure to install a new axle nut and tighten it properly. Use lock washers or lock nuts on all axles.

Brake Maintenance and Inspection

Check brakes for proper operation. If brakes slip due to worn or damaged wheels, replace the wheels immediately and retest the brakes. If the brake mechanism itself is not operating properly